The BRCGS Packaging Certification is an internationally renowned standard that makes sure that packaging materials are safe, quality, and have better workflow requirements. This packaging safety certification is broadly accepted by the Global Food Safety Initiative (GFSI) and helps businesses level up following rules, reduce risks, and build consumer trust.

In this detailed guide, we will read about:

- What is BRCGS Packaging Certification and its importance?

- BRCGS certification benefits

- How to get BRCGS Packaging Certification in India?

- A breakdown of BRCGS Issue 7 clauses

- BRCGS certification cost

- How Legal4sure can help you with the BRCGS packaging certification process

- Case studies that show our real success stories

To have the best guidance from our BRCGS certification consultants in India, contact us now!

What is BRCGS Packaging Certification?

BRCGS packaging certification (Brand Reputation through Compliance Global Standards) ensures that companies producing packaging materials for food, consumer goods, and other applications follow all safety and quality standards. It also helps reduce the possible risk in your supply chain, maintain clarity and transparency, and gain customer support

There are two categories in this:

➜ Category 1: Packaging that comes into direct contact with food.

➜ Category 2: Packaging for indirect contact (outer packaging, labels, etc).

Read More: What Is BRCGS Certification? Everything You Need To Know

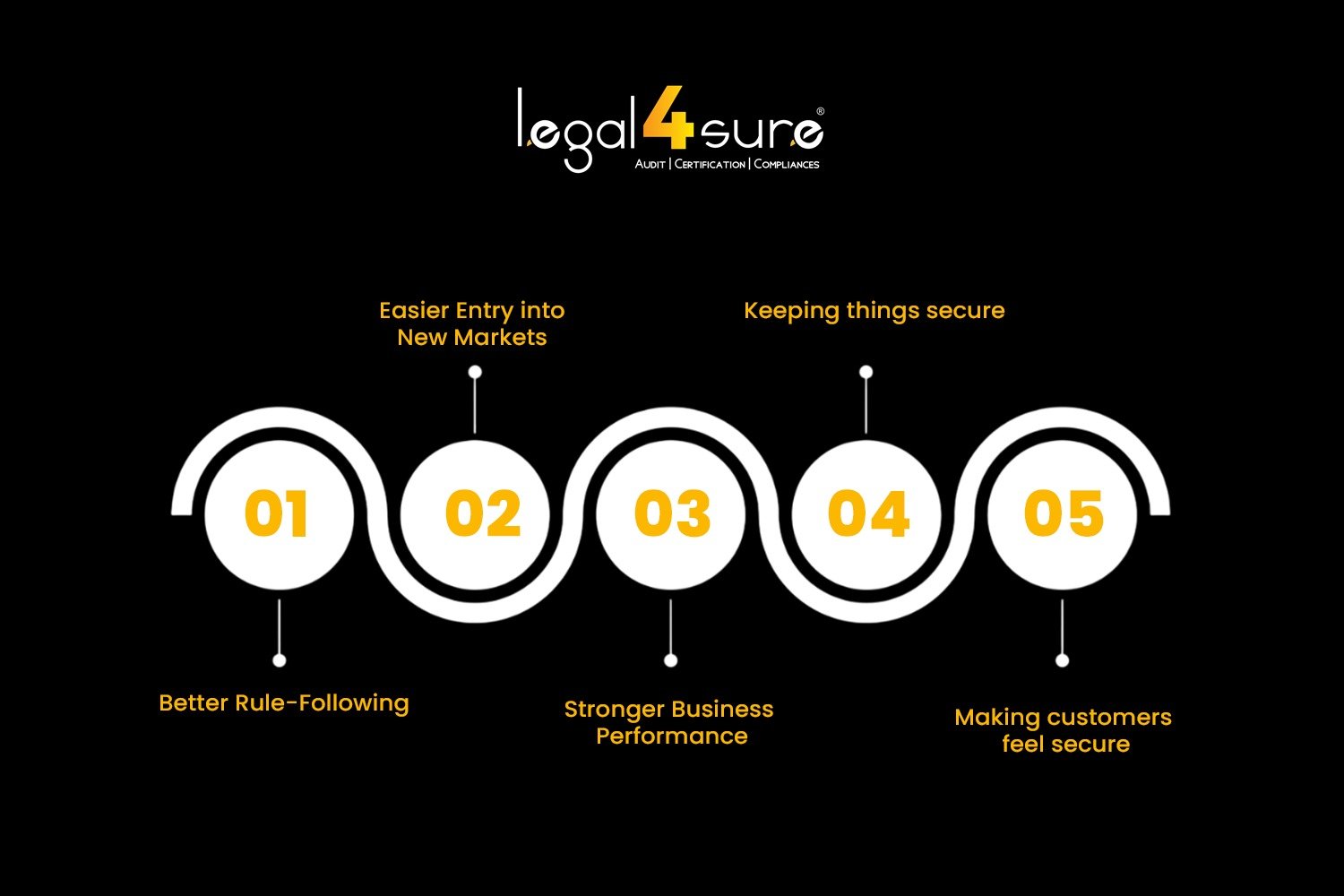

Benefits of BRCGS Packaging Certification

1. Better Rule-Following

BRCGS packaging certification makes sure to follow all rules and regulations with regulatory and legal requirements, decreasing the risk of non-compliance penalties.

2. Easier Entry into New Markets

Trusted by the GFSI and global retailers, this packaging safety certificate makes your business well-trustable and helps you expand your business horizons and sell in more countries.

3. Stronger Business Performance

The use of simple steps helps avoid mistakes, reduce waste, and work fast, saving money and getting more done.

4. Keeping things secure

BRCGS packaging certification helps avoid issues like impurity, product recalls, and poor quality, making the supply chain safer.

5. Making customers feel secure

A certified business earns customer trust by showing it cares about safety and quality.

Do you also want to have such benefits in your company? Get connected with us and have BRCGS packaging certification easily!

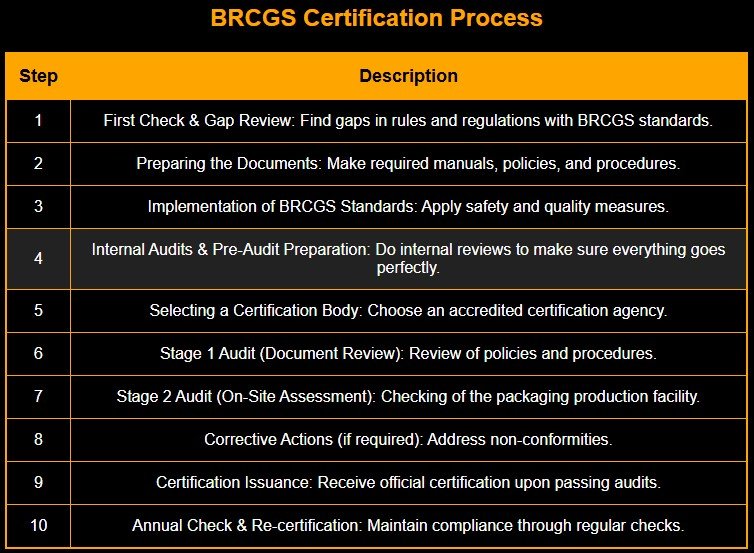

Step-by-Step BRCGS Packaging Certification Process

BRCGS Issue 7 Clauses

| Clause Number | Clause Title | Description |

| 1 | Senior Management Commitment | Make sure top-level management supports the certification. |

| 2 | The BRC Food Safety Plan – HACCP | Finding and reducing possible risks. |

| 3 | Food Safety & Quality Management System | Applying quality management methods. |

| 4 | Site Standards | Maintenance of the facility and better workflow process. |

| 5 | Product & Process Control | Makes sure production processes follow all the safety norms |

| 6 | Personnel | Training and competency management. |

| 7 | Product Defense & Food Fraud Prevention | Protect of Knowingly spoiling. |

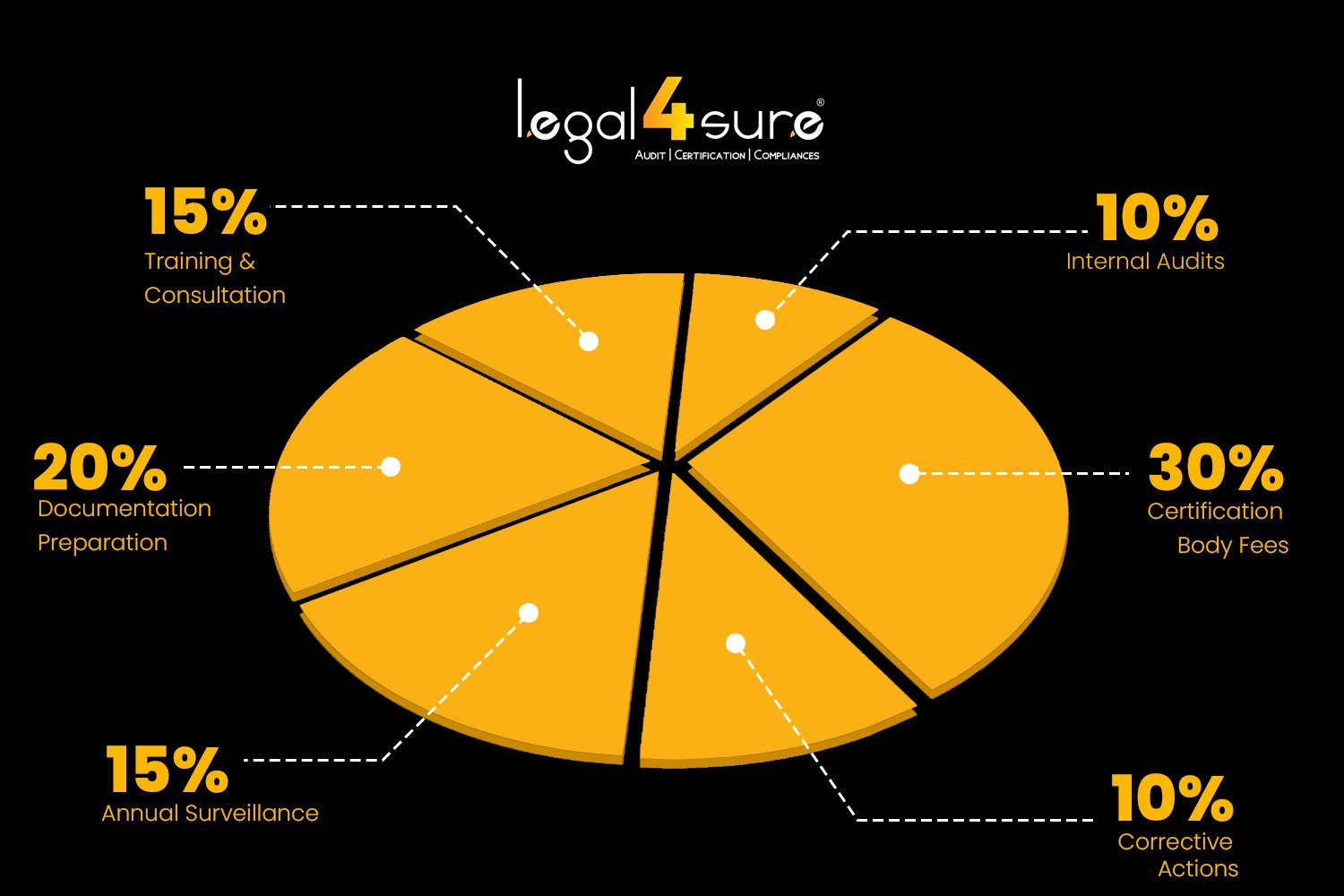

Cost Breakdown for BRCGS Packaging Certification in India

1. Documentation Preparation (20%)

The most important thing is the documentation preparation for BRCGS packaging certification. This involves preparing quality manuals, policies, risk analysis, process documentation, and performance matches so that all safety and flow requirements are met. Our BRCGS experts will help you in preparing and maintaining the documents for a smooth and easy BRCGS audit.

2. Training & Consultation (15%)

Your team needs help to understand BRCGS packaging standards, risk management, and audit requirements through proper training. Your business is thoroughly guided through compliance processes through expert consultation. We will provide you with complete training for your employees to let them know the complete BRCGS packaging standards.

3. Internal Audits (10%)

Internal audits find the gaps, risks, and non-compliance ahead of the actual certification audit. These audits make sure that corrective actions are undertaken as a precautionary mechanism for minimizing the risk of audit failure. Our experts will conduct internal audits in your company to identify the non conformities and fix them to have a successful BRCGS audit.

4. Certification Body Fees (30%)

The biggest component of cost for BRCGS certification for food contact packaging is the fee you pay the accredited certification body to carry out stage 1 and stage 2 audits, issue the certification, and provide formal recognition of compliance.

5. Corrective Actions (10%)

Facing all the challenges and clearing all the issues found during audits is crucial. This consists of process improvements, staff training, and system updates to meet BRCGS requirements and to provide a smooth and clear certification process. Our BRCGS consultants can help you with the proper corrective action plan to improve your business and fix, if any, non-conformities.

6. Annual Surveillance (15%)

These regular surveillance audits are put in place to make sure that compliance is maintained and that certification can be sustained. These audits allow companies to keep up with changes in BRCGS requirements and avoid penalties or suspension of certification.

Legal4sure’s Step Consulting Process

First Talk & Gap Review

We will do a complete analysis of the processes you were working on, where gaps are found, and corrective actions are used for a smooth transition to BRCGS requirements.

Checking Your Documents

Our team members review relevant documents, policies, and records that you currently have, making sure they comply with BRCGS packaging standards.

Helping You Put It in Place

We take you step-by-step through how to implement BRCGS standards in your packaging operations for a successful transition.

Training to Spot and Manage Risks

Equips your team to find/manage/minimize risks in BRCGS certification packaging materials production in compliance.

Training for In-House Audits

We prepare your team to carry out internal audits effectively so that you are ready for official BRCGS certification audits.

Fixing Issues and Improving Processes

In the case of finding issues, we quickly work to implement appropriate corrective actions to bring the certification up to standard.

Working with the Certification Team

We help in selecting and coordinating with an accredited certification body for a hassle-free audit process.

Stage 1 Audit Preparation

We make sure your documentation, policies, and processes are audit-ready for the first certification stage.

Stage 2 Audit Preparation

We help you prepare for the final audit, addressing any gaps to ensure a successful certification.

Ongoing Support After Certification

Even after certification, we offer ongoing support to maintain compliance and prepare for future audits.

Legal4sure’s Successful Case Studies for BRCGS Packaging Certification

Case Study 1: Aeroplast’s Journey to BRCGS Packaging Certification

Background:

Aeroplast aimed to expand into international markets and required BRCGS Packaging Certification to meet global standards.

Challenge:

The company faced two major hurdles: incomplete documentation and insufficient training for its staff on hygiene and quality practices.

Solution:

We stepped in with a modified approach by providing end-to-end personnel training and implementing strong hygiene protocols to align with BRCGS requirements in their company.

Result:

Within just 6 months, Aeroplast successfully achieved BRCGS Packaging Certification, resulting in a 20% growth in operational efficiency.

Case Study 2: Pouch Packaging Factory Aligns with BRCGS Issue 7 Standards

Background:

A leading pouch packaging manufacturer sought to comply with BRCGS Issue 7 to maintain its global reputation and meet industry standards.

Challenge:

The company was initially non-compliant with several key clauses, posing a risk to certification success.

Solution:

Our BRCGS consultants implemented powerful risk assessment procedures and delivered targeted training to the personnel team to address compliance gaps.

Result:

They got BRCGS for pouch packaging factory with smooth certification audits and zero major non-compliance findings.

Do you also want that success in your business? Get a Free Consultation Now!

Get Started with Legal4sure Today!

The BRCGS Packaging Certification transforms packaging manufacturers into effective global safety standard operators while building customer trust and workflow performance improvement. With our perfect guidance, you don’t have to fight the challenges of the certification process all alone. We are here for your BRCGS packaging audit preparation. Our successful record, along with structured methodology and direct assistance, leads to smooth certification processes for all our clients. Contact Legal4sure now for your free consultation to begin our work in making your packaging business BRCGS certified, along with future-ready operations.

Contact us now to Get Started!

Contact No: +91-9310655040, +91 9971894121

Email: info@legal4sure.in

Frequently Asked Questions

What is BRCGS packaging certification?

BRCGS Packaging certification is a globally recognized standard ensuring the safety, quality, and legality of packaging materials and products used in food manufacturing, retail, and other industries. It sets criteria for the production, packaging, storage, and distribution of materials to ensure product safety and quality.

Who needs BRCGS packaging certification in India?

- Manufacturers of packaging and packaging materials

- Companies that handle upstream processes for packaging

- Suppliers of packaging materials

- Manufacturers of disposable food packaging

- Companies involved in the food supply chain

What documents are required for BRCGS packaging certification?

- Quality Management System

- Hazard and Risk Assessment

- Supplier and Raw Material Arrangement

- Product specifications and Traceability

- Production and process control documents

- Good Manufacturing Practices (GMP)

- Training and Competency Records

- Internal Audits and Management Review

- Site Security and Product Defense

- Legal and Regulatory Compliance

Who needs BRCGS packaging certification in India?

- Manufacturers of packaging and packaging materials

- Companies that handle upstream processes for packaging

- Suppliers of packaging materials

- Manufacturers of disposable food packaging

- Companies involved in the food supply chain

What are the common BRCGS audit challenges?

- Understanding and applying the standards

- Maintaining proper documentation and records

- Ensuring consistent employee training,

- Managing the supply chain effectively

- Addressing non-conformities promptly