Food processing facilities in India are competing to meet world safety standards. Passing an FSSC 22000 audit might reduce the risk of recalls, enhance the confidence of retailers, and provide doors to export contracts. Still, some plants die from their failure to perform basic, daily activities. 10 Simple actions transform complex criteria into ten straightforward ones in this blog, the FSSC 22000 audit Checklist for Indian Factories. Following their recommendations at every stage should let you approach your next audit with greater assurance. Less like a test and more like a quick evaluation of your growth, should it feel.

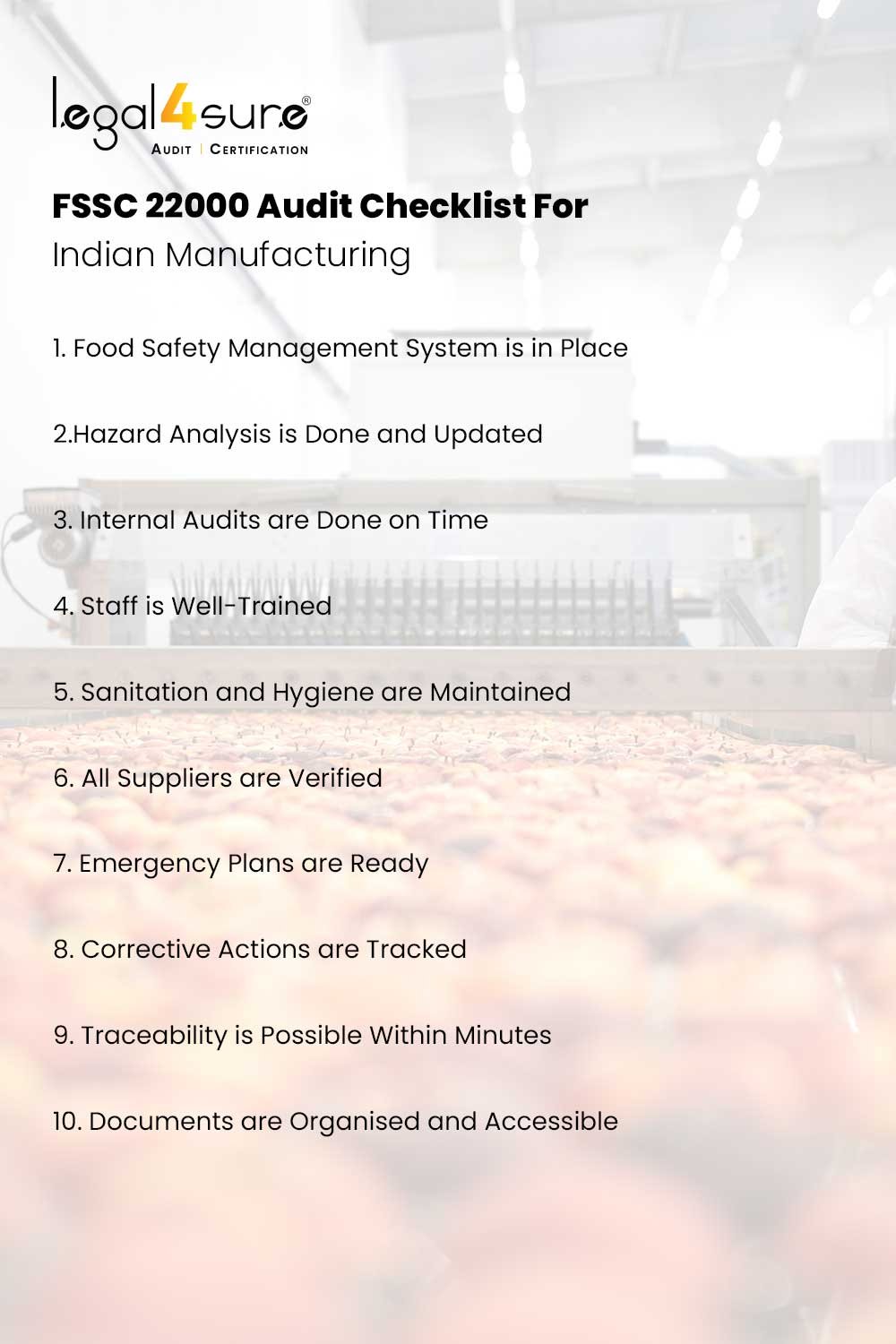

FSSC 22000 Audit Checklist For Indian Manufacturing

To help you prepare better, here’s a complete FSSC 22000 audit checklist for Indian factories. In the next section, we’ll walk you through 10 essential steps to review your factory’s readiness

1. Food Safety Management System is in Place

Check that your FSMS is well-structured and reliable. It ought to be based on ISO 22000. Your FSMS needs to contain policies, goals, and strategies for risk monitoring. Maintain current and prepared documentation. The cornerstone of FSSC 22000 compliance is this mechanism.

2. Hazard Analysis is Done and Updated

A thorough Hazard Analysis and Critical Control Points (HACCP) should be carried out. This process analyses possible food processing flaws. Particularly following any change in output, your team should regularly update the HACCP plan.

3. Internal Audits are Done on Time

Conduct fssc 22000 internal audit checklist at least once yearly. These aid in spotting issues before the final audit. Record every result found as well as any actions taken. This indicates a strong safety culture and proactive mindset within your team.

4. Staff is Well-Trained

Your team must understand the basics of food safety. Provide training frequently. Every employee has to understand their responsibilities, hazard points, and cleanliness. Have records ready for the auditor’s review.

5. Sanitation and Hygiene are Maintained

Good hygiene is a must. From raw material storage to packaging, cleanliness should be visible everywhere. There should be cleaning schedules, logs, and assigned responsibilities. Restrooms, staff uniforms, and handwashing facilities must be kept clean and in good condition.

6. All Suppliers are Verified

Only use authorised providers. Perform a risk analysis for each. Verify quality records, audits, and certificates. Prepare documentation demonstrating that the materials you purchase are both legal and safe.

7. Emergency Plans are Ready

Prepare for possible risks such as product recalls, natural calamities, or equipment failures. Your team must be aware of its responsibilities. Maintain an up-to-date emergency plan and test it with practice sessions.

8. Corrective Actions are Tracked

You have to take prompt action to address any problems that arise. Most significantly, keep track of the reasons behind the occurrence and its resolution. Make a clear record of each corrective measure. This demonstrates to auditors that you are organised and accountable.

9. Traceability is Possible Within Minutes

You must immediately rectify any issues. Focus primarily on understanding why the issue occurred and documenting the solution. Keep track of each remedial measure in detail. This demonstrates to auditors that you are methodical and accountable.

10.Documents are Organised and Accessible

Auditors will request documentation. Among them are training logs, cleaning reports, internal audit results, grievances, and other items. Keep these items together. If you use digital systems, make sure access is simple.

Some Indian factories overlook minor but significant procedures. Check these as well:

- Only licensed suppliers should perform pest management logs, and they must be kept up to date.

- Equipment calibration should be performed frequently, and records maintained.

- A glass and breakable material register must be kept in processing areas.

- The factory layout should facilitate the seamless movement of workers and materials.

If neglected, these little aspects might cause audit failure.

Be Ready Before The Auditor Arrives

Conduct a mock audit with your team. Take a stroll around each section. Ask staff members simple questions about food safety. Verify documentation immediately. Check for comissions in hygiene or documentation. Address them right away. You can also use outside experts to conduct a gap analysis. This gives you a good notion of what needs to be improved before the formal FSSC 22000 inspection.

Benefits Of Using An FSSC 22000 Audit Checklist For Indian Factories

The reasons why this FSSC 22000 Audit Checklist for Indian Factories is essential are as follows:

- Reduces stress and time during audits,

- improves the Possibility of initial acceptance

- Establishes client trust with a proven system.

- It helps Indian companies comply with export standards.

- Enhances food safety culture and everyday procedures

With this FSSC 22000 Audit Checklist for Indian Factories in place, your plant is not only audit-ready but also operating effectively and efficiently.

Obtaining FSSC 22000 accreditation may help you expand your company and break into new markets. However, effective preparation is necessary to pass the audit. You may prepare your team, systems, and papers in advance by utilizing this 10-point FSSC 22000 audit checklist for Indian factories. Follow the checklist step-by-step, keep things organised, and educate your employees. It’s the best way to be prepared and confident for the upcoming inspection.

Let Legal4sure handle your audit worries. Book a Free consultation now.

Our experts specialise in FSSC 22000 compliance for Indian factories. Get personalised guidance, avoid last-minute panic, and pass your audit with confidence

FAQ

Q1. What is the FSSC 22000 Audit Checklist for Indian Factories?

A list of requirements to verify food safety management compliance in factories.

Q2. How to audit a factory for FSSC 22000?

Review documents, inspect operations, and verify PRPs and HACCP implementation.

Q3. What is an FSSC 22000 audit?

A formal evaluation of a food business against FSSC 22000 standards.

Q4. How to prepare a compliance checklist?

List all FSSC 22000 clauses, PRPs, HACCP steps, and regulatory requirements.

Q5. What are the 5 C’s of FSSC 22000 audit?

Commitment, Control, Communication, Compliance, and Corrective actions.

Q6. How to create an audit checklist?

Include documentation review, operational checks, risk assessment, and record verification.

Q7. What are the 4 types of FSSC 22000 audits?

Internal, second-party, third-party, and recertification audits.

Q8. What are the 7 audit procedures with examples?

Planning, opening meeting, document review, site inspection, interviews, observations, closing meeting.