A factory may lose its position in international supply chains in today’s cutthroat worldwide industry if it fails a single audit or receives a poor compliance score. Why Indian factories lose global export orders can frequently be found in disregarded worldwide criteria such as BRCGS, subpar documentation, and shortcomings in food safety or ethical behaviour. Let’s examine the primary factors that are preventing Indian producers from succeeding on a global scale.

Global buyers expect more

Foreign customers’ decisions are no longer solely motivated by pricing or output. They look for plants that meet worldwide known certifications like BRCGS (Brand Reputation Compliance Global Standards), which provide customers confidence that your site complies with standards for food safety, hygiene, moral sourcing, and sustainability. They reveal your presence. Many Indian factories ignore the significance of this. They believe that orders will keep coming in as a result of solid links or a rich history. International customers, however, are looking for systems rather than narratives.

Weak compliance with BRCGS standards

Poor or inconsistent adherence to BRCGS standards is one of the main reasons why Indian factories lose global export orders. For instance, the BRCGS Global Standard for Food Safety mandates thorough procedures for traceability, hazard analysis (HACCP), hygiene, allergen control, and internal audits.

A third-party inspection can lead to a failed audit if even a single element is missing. In many manufacturing facilities, records are poorly maintained or incomplete, making it difficult to show that your business has a strong, trustworthy system to keep food safe, every step of the way..

Although certain businesses do implement practices, they won’t be acknowledged by certification organisations unless they are documented or monitored.

Read More: How to prepare for a brcgs audit

Lack of trained staff and awareness

Many managers and operations staff members are uninformed of international standards. Training may be limited to manufacturing skills and omit adherence, cleanliness, or documentation methods. More than surface-level hygiene, a BRCGS audit assesses the structure of systems, role clarity, and process consistency. If your quality control personnel are not aware of what auditors look for, failure is simple. Even little mistakes, such as unclear labelling, inadequate storage, or insufficient cleaning schedules, can lead to significant audit non-conformities.

Poor internal audit culture

Think of internal audits as practice runs for obtaining international certifications. On the other hand, several Indian factories see audits as simple checklists that are either ignored or done half-heartedly. An effective internal audit process serves as your early warning system, enabling you to find issues before external auditors do. A significant cause of. Why Indian factories lose global export orders is that they are frequently unprepared when real inspections take place. On the other hand, factories that consistently pass BRCGS or similar inspections regularly undertake valuable internal assessments, fostering a culture of compliance that international consumers value.

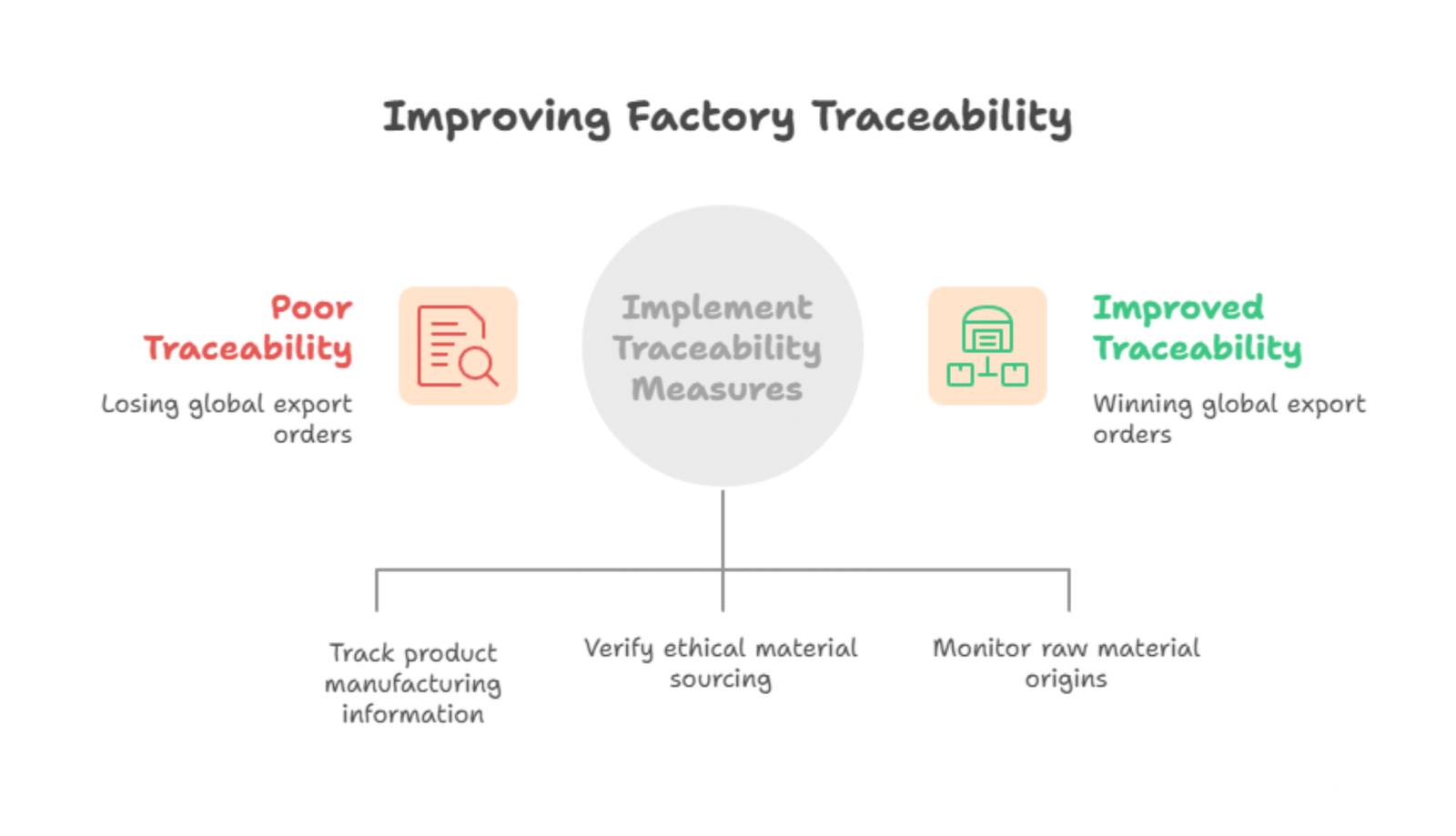

Lack of traceability and supply chain control

Insufficient traceability is another reason why Indian factories lose global export orders. Global buyers demand complete transparency throughout their supply chains, from the raw materials to the finished goods delivery. They are interested in learning about the origin of your materials, the methods used to process them, and the adherence to ethical standards.

A factory is considered dangerous if it lacks effective batch coding, vendor approval procedures, and ingredient tracking. Because of this, it’s harder for them to win or keep contracts with big retailers or importers in places like the EU, the UK, or the USA.

Inadequate investment in infrastructure

A BRCGS audit can be against you if your factory layout is bad, your equipment is old, or your facilities are old. Many factories concentrate on output capacity while ignoring essential structural needs such as pest-proofing, drainage, illumination, and hygiene zoning.

Modern facilities that adhere to safety and efficiency standards are what foreign purchasers anticipate. Red flags will be raised by any facility that does not demonstrate this dedication, regardless of the calibre of your goods.

Poor handling of customer complaints

The way you handle complaints reveals a lot about your factory’s systems. Factories are required by BRCGS to have a clear complaint-handling process in place. However, several Indian producers do not keep adequate records, conduct thorough root cause analyses, or take appropriate follow-up steps. This is one of the reasons why Indian factories lose global export orders buyers see it as a sign that quality control and customer satisfaction are not taken seriously. Even a single complaint lost due to mismanagement can damage your reputation and cost you valuable contracts.

Ethical sourcing and worker welfare concerns

Global purchasers are increasingly concerned about how you treat your employees in the age of conscious consumerism. Factories are required to demonstrate adherence to ethical trade standards, which include no forced labour, fair pay, reasonable working hours, and a focus on health and safety.

The BRCGS Ethical audit can help evaluate this, but many Indian manufacturers are not ready. Buyers move quickly to more transparent providers when they see a danger of harm to their reputation.

Legal4sure Keeps Indian Factories Winning Export Orders

So, why Indian factories lose global export orders? It’s no longer about price or capacity. The real game is trust, transparency, and alignment with global standards like BRCGS. Factories that ignore certification, training, and ethical systems often end up losing not just audits but also long-term international buyers.

If you’re serious about global trade, your factory must be ready to meet these expectations every single day. That’s where Legal4sure steps in — with expert food certification and audit support to keep you compliant, trusted, and globally competitive.

Turn Checklists into Checkpoints to the World

Legal4sure helps Indian factories transform audits into opportunities. Align with BRCGS, impress global buyers, and ship success every time.