If your plant wants global orders in 2025, food safety alone won’t be enough. Buyers want to see what’s behind the certificate, including your energy use, worker welfare, and long-term impact on the environment. That’s why BRCGS and ESG compliance for manufacturing plants has become essential. It’s not just about passing an audit. It’s about staying relevant, earning trust, and showing that your factory can deliver on products and values.

How the BRCGS Certification Process Connects with ESG Goals

The BRCGS certification process has always been based on building trust by using food safety, hygiene, and traceability. Now, buyers are merging this with ESG. So, if your factory has good food safety systems but poor waste management, you won’t make the approved supplier list.

Audits now cover much more than just hygiene and paperwork. Documentation is still important, but your real-world impact matters too. Can your plant showcase its ability to manage risk rather than just reacting to it? If you want to stay ahead, BRCGS and ESG compliance for manufacturing plants must be integrated, not isolated.

Sustainability in Manufacturing Is No Longer Optional

Whether you’re a small food unit or a large packaging plant, sustainability in manufacturing is a requirement now. Buyers want to know how you’re reducing waste, managing resources, and improving efficiency without harming the planet.

This isn’t just for show. Sustainability can save your money, too. By reusing rinse water or reducing energy, or switching to recyclable materials, your profits can increase! And don’t forget, as you prepare for your next BRCGS and ESG audit, these efforts will add to your story.

This is why BRCGS and ESG compliance for manufacturing plants is a smart choice, beyond just meeting requirements.

BRCGS and ESG Audit Preparation Tips That Work

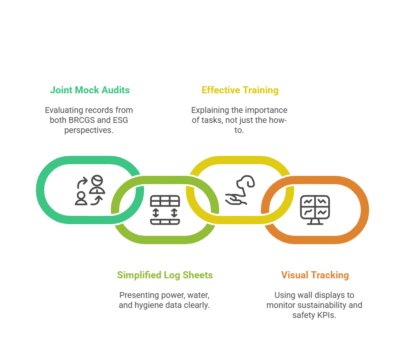

Audit preparation should never be last-minute. The best plants treat it as ongoing work, part of daily routines, not a rush during audit season. Use these BRCGS and ESG audit preparation tips to build readiness all year:

- Run joint mock audits: Evaluate your records through both BRCGS and ESG perspectives.

- Simplify log sheets: Present power, water, and hygiene data.

- Train effectively: Don’t just explain “what to do.” Explain “why it matters.”

- Use visuals on walls: Track sustainability KPIs along with food safety metrics.

Auditors don’t expect perfection. They expect awareness, action, and improvement. That’s what BRCGS and ESG compliance for manufacturing plants is all about.

What is Environmental and Social Compliance in BRCGS

So where does ESG currently fit in BRCGS? While not titled as such, elements of environmental and social compliance are already part of Issue 9. Worker safety, ethically sourced, grievance mechanisms, and supplier monitoring should form an important part of your audit.

If you’re a factory preparing for certification, don’t overlook these social and environmental indicators. Map them out. Strengthen them. Train your teams to discuss them.

This is where BRCGS and ESG compliance for manufacturing plants intersect — in real systems, not just jargon. That’s what buyers want to see.

Global Buyer Expectations for ESG and BRCGS in 2025

Global buyer expectations for ESG and BRCGS in 2025 are higher than ever. Audits are not just technical; they’re ethical. They reflect the brand’s public commitments to responsible sourcing, ethical trade, and sustainability.

If you want to repeat your business, your plant must meet these expectations. That means:

- Having ESG metrics ready to present.

- Clearly stating your sustainability goals.

- Supporting claims with records that hold up in audits.

This is no longer a bonus; it’s part of standard supplier evaluation. It positions BRCGS and ESG compliance for manufacturing plants at the heart of every export conversation.

Is ESG Mandatory for BRCGS Certified Suppliers in 2025?

No, ESG may not yet be a formal requirement in the BRCGS checklist—but buyer expectations have changed. It is no longer enough to have a food safety certificate. You are also expected to describe how you are managing emissions, water use, and working conditions. Many suppliers are losing contracts, not because they have failed in safety, but because they have failed in transparency and accountability. In 2025, BRCGS & ESG compliance for manufacturing plants has become a benchmark, not just for compliance but for trust.

How Indian Manufacturing Plants Can Align with BRCGS and ESG Goals

The good news is you don’t need two separate systems. How Indian manufacturing plants can align with BRCGS and ESG goals involves integration. Use your existing BRCGS framework as a base and incorporate ESG into it.

- For your pest control records, add data on eco-friendly chemicals used.

- For your supplier approvals, include ESG screening.

- For your employee files, add training on safety, rights, and well-being.

- For your waste logs, track recyclable and hazardous waste.

The more seamlessly these elements fit into your system, the easier your audits become. Stronger relationships with buyers will follow. That’s the true strength of BRCGS and ESG compliance for manufacturing plants.

Steps to Prepare for BRCGS and ESG Audits in Food Units

These steps for preparing for BRCGS and ESG audits in food units work whether you’re a small or large manufacturer:

- Review policies: Make sure that ESG-related risk is in your procedures.

- Collect data accurately: Not just hygiene audit checks, but energy, waste, and water checks.

- Talk with your team: Make it a point to discuss ESG-related measurements in team meetings, not just HR meetings.

- Address gaps early: Waiting for audits to act is the slowest route to compliance.

Food units that build systems gradually outperform those that panic during BRCGS certification audits. They also establish stronger credibility with both buyers and certifiers.

Legal4Sure: Your Partner for BRCGS + ESG Success

At Legal4sure, we work with factories to make BRCGS and ESG compliance simple, clear, and audit-ready, without the stress. If your plant needs real support, not vague advice, we’ll help you fix gaps, train your team, and meet buyer expectations, the way it should be done.

Contact Legal4sure