FSSC 22000 (Food Safety System Certification) is an internationally recognized food safety standard for manufacturers, processors, packaging companies, distributors, and storage facilities. Built on ISO 22000, this certification ensures safe food production, strengthens supply-chain transparency, and helps organizations comply with global food safety regulations.

The latest Version 6 introduces stricter requirements to enhance consumer safety, reduce operational risks, and promote sustainability across the food industry.

What is FSSC 22000?

FSSC 22000 Certification combines:

- ISO 22000: Food Safety Management System (FSMS)

- Sector-specific Pre-Requisite Programs (PRPs)

- Additional FSSC 22000 requirements

This integrated system provides a complete approach to food safety, covering hazard analysis, operational control, traceability, and compliance. Organizations certified under FSSC 22000 demonstrate a strong commitment to producing safe, high-quality food.

Who Should Get FSSC 22000 Certification?

The certification is essential for a wide range of food businesses, including:

- Food processing and manufacturing units

- Packaging material producers

- Warehousing and distribution facilities

- Ingredient suppliers

- Catering and hospitality providers

- Retail and wholesale food supply chains

By obtaining FSSC 22000 Certification, these businesses show their commitment to reliable and consistent food safety practices.

Get Your FSSC 22000 Certification

Legal4sure helps food brands plan, prepare and successfully pass FSSC 22000.

Talk to our BRC experts and start your certification journey today.

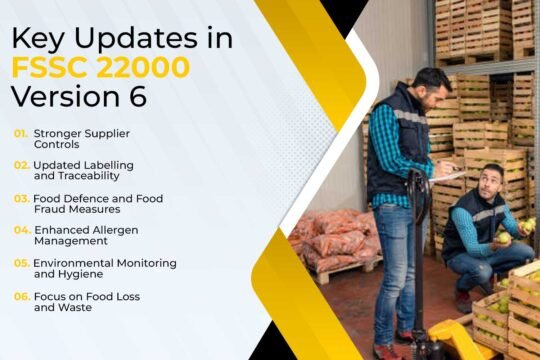

Key Updates in FSSC 22000 Version 6

Version 6 introduces significant changes to strengthen food safety compliance and align with international expectations. Key updates include:

1. Stronger Supplier Controls

Companies must verify, approve, and continually monitor suppliers of raw materials, packaging, and ingredients. Documented evidence of supplier assessments ensures safety across the supply chain.

2. Updated Labelling and Traceability

Labels and traceability records must be accurate, including batch numbers, ingredient details, and production data. This reduces errors, prevents mislabelling, and ensures regulatory compliance.

3. Food Defence and Food Fraud Measures

Mandatory risk assessments are required to prevent intentional contamination and fraudulent practices such as misrepresentation or adulteration. Companies must implement and document controls to address these risks.

4. Enhanced Allergen Management

Version 6 emphasizes preventing allergen cross-contact through dedicated handling zones, validated cleaning procedures, proper labelling, and staff training.

5. Environmental Monitoring and Hygiene

Stricter monitoring of production environments, equipment, and sanitation practices ensures safe manufacturing conditions and minimizes contamination risk.

6. Focus on Food Loss and Waste

Facilities must track, measure, and reduce food loss and waste. This not only promotes sustainability but also increases operational efficiency.

FSSC 22000 Certification Requirements

To meet certification standards, organizations need to:

- Establish a documented Food Safety Management System (FSMS)

- Conduct hazard analysis and risk assessments

- Implement sector-specific Pre-Requisite Programs (PRPs)

- Maintain documented supplier approval and monitoring processes

- Develop Food Defence and Food Fraud plans

- Maintain traceability and recall systems

- Conduct internal audits

- Train staff on food safety protocols

- Implement hygiene, sanitation, and equipment maintenance procedures

- Maintain complete records and documentation

Step-by-Step Certification Process

Step 1: Gap Assessment

Compare your current system with Version 6 requirements to identify gaps and weaknesses.

Step 2: Documentation and Implementation

Prepare manuals, SOPs, hazard analysis reports, PRPs, and operational controls.

Step 3: Internal Audit

Conduct internal audits to ensure compliance and identify areas that need improvement.

Step 4: Management Review

Senior management reviews audit findings, addresses gaps, and approves corrective actions.

Step 5: Stage 1 Audit (Documentation Review)

The certification body reviews your documentation, procedures, and preparedness.

Step 6: Stage 2 Audit (On-Site Inspection)

Auditors check production practices, hygiene, equipment, traceability, and records in person.

Step 7: Certification Decision

If compliant, your organization receives FSSC 22000 Certification.

Step 8: Surveillance Audits

Periodic audits ensure continuous compliance and help maintain the certification.

Benefits of FSSC 22000 Certification

- Ensures safe food production and hygiene

- Minimizes contamination and operational risks

- Aligns with international regulations

- Enhances access to domestic and global markets

- Builds consumer and buyer trust

- Improves supply-chain transparency

- Supports sustainability and reduces food waste

- Promotes operational efficiency and consistency

Cost and Duration of Certification

Certification costs depend on:

- Organization size

- Number of products

- Number of employees

- Complexity of operations

The process typically takes 30–90 days, depending on your readiness and the quality of documentation.

You May Also Like : Cost of FSSC 22000 Certification

How Legal4sure Can Help

Legal4sure provides full support for:

- Gap analysis and readiness assessment

- Documentation and SOP preparation

- PRP implementation

- Staff training and internal audits

- Food Defence and Food Fraud planning

- Assistance during certification audits

We help organizations transition to Version 6 smoothly and maintain long-term compliance with FSSC 22000 standards.

Get Professional Help for Your FSSC 22000 Certification

Our team at Legal4sure provides complete support for FSSC 22000 documentation, internal audits, compliance checks, and certification preparation. Get personalized guidance for your organization’s FSSC 22000 journey.

FAQ’s (Frequently Asked Questions)

Q1. What is FSSC 22000?

FSSC 22000 is a globally accepted, GFSI-benchmarked food safety certification scheme for food and food packaging manufacturers, based on ISO 22000, technical standards for prerequisite programs (PRPs), and additional FSSC requirements.

Q2. What is the difference between ISO 22000 and FSSC 22000?

ISO 22000 is only the management system standard. FSSC 22000 is a full GFSI-recognized certification scheme that includes ISO 22000 + sector-specific PRPs (e.g., ISO/TS 22002-1) + extra FSSC requirements. Only FSSC 22000 is accepted by most global retailers.

Q3. Is FSSC 22000 recognized by GFSI?

Yes, FSSC 22000 is fully recognized by the Global Food Safety Initiative (GFSI) and accepted by major retailers like Walmart, Tesco, Costco, Carrefour, Aldi, and more.

Q4. Who needs FSSC 22000 certification?

Food manufacturers, ingredient suppliers, food packaging producers, catering, storage, and transport companies supplying to international retailers or seeking top-tier food safety certification.

Q5. What is the latest version of FSSC 22000?

The current version is FSSC 22000 Version 6, released in April 2023 and mandatory for all audits since April 1, 2024.

Q6. How long does it take to get FSSC 22000 certified?

Usually 6 to 18 months, depending on company size and current system readiness. Stage 1 audit follows documentation completion, with Stage 2 typically 3–6 months later.

Q7. How much does FSSC 22000 certification cost?

Costs typically range from €8,000 to €50,000+ depending on company size, scope, and location (includes audit fees, consultancy if used, and internal efforts).

Q8. How often are FSSC 22000 audits conducted?

Initial certification involves Stage 1 and Stage 2 audits. After certification: one surveillance audit every year and a full recertification audit every 3 years.

Q9. Can small companies achieve FSSC 22000 certification?

Yes, absolutely. The scheme is fully scalable, and thousands of small and medium-sized food businesses worldwide are successfully FSSC 22000 certified.

Q10. Which major companies are FSSC 22000 certified?

Over 30,000 sites in 190+ countries, including Nestlé, Unilever, Coca-Cola, Danone, PepsiCo, Mondelēz, Kraft Heinz, and most private-label suppliers to global retailers.