Legal4sure is India’s trusted FSSC 22000 certification partner. With over a decade of experience, we help food, packaging, and storage units build strong safety systems, pass audits confidently, and meet global buyer expectations.

Legal4sure is India’s trusted FSSC 22000 certification partner. With over a decade of experience, we help food, packaging, and storage units build strong safety systems, pass audits confidently, and meet global buyer expectations.

FSSC 22000 Sectors: Food Manufacturing, Food Ingredient Manufacturing, Farming (limited cases), Animal Feed Manufacturing, Packaging for Food, Transport & Storage, Retail & Catering

FSSC 22000 Sectors: Food Manufacturing, Food Ingredient Manufacturing, Farming (limited cases), Animal Feed Manufacturing, Packaging for Food, Transport & Storage, Retail & Catering

FSSC 22000 Sectors: Food Manufacturing, Food Ingredient Manufacturing, Farming (limited cases), Animal Feed Manufacturing, Packaging for Food, Transport & Storage, Retail & Catering

FSSC 22000 Sectors: Food Manufacturing, Food Ingredient Manufacturing, Farming (limited cases), Animal Feed Manufacturing, Packaging for Food, Transport & Storage, Retail & Catering

FSSC 22000 Sectors: Food Manufacturing, Food Ingredient Manufacturing, Farming (limited cases), Animal Feed Manufacturing, Packaging for Food, Transport & Storage, Retail & Catering

FSSC 22000 Sectors: Food Manufacturing, Food Ingredient Manufacturing, Farming (limited cases), Animal Feed Manufacturing, Packaging for Food, Transport & Storage, Retail & Catering

FSSC 22000 Sectors: Food Manufacturing, Food Ingredient Manufacturing, Farming (limited cases), Animal Feed Manufacturing, Packaging for Food, Transport & Storage, Retail & Catering

FSSC 22000 Sectors: Food Manufacturing, Food Ingredient Manufacturing, Farming (limited cases), Animal Feed Manufacturing, Packaging for Food, Transport & Storage, Retail & Catering

FSSC 22000 Sectors: Food Manufacturing, Food Ingredient Manufacturing, Farming (limited cases), Animal Feed Manufacturing, Packaging for Food, Transport & Storage, Retail & Catering

FSSC 22000 Sectors: Food Manufacturing, Food Ingredient Manufacturing, Farming (limited cases), Animal Feed Manufacturing, Packaging for Food, Transport & Storage, Retail & Catering

FSSC 22000 Sectors: Food Manufacturing, Food Ingredient Manufacturing, Farming (limited cases), Animal Feed Manufacturing, Packaging for Food, Transport & Storage, Retail & Catering

FSSC 22000 Sectors: Food Manufacturing, Food Ingredient Manufacturing, Farming (limited cases), Animal Feed Manufacturing, Packaging for Food, Transport & Storage, Retail & Catering

Legal4sure has delivered 1500+ FSSC 22000 certification audit successes, trained 4500+ QA professionals, and partnered with 25+ top certifiers to build globally trusted food safety systems for India’s leading factories.

Legal4sure fast-tracks your FSSC 22000 certification in just 30 days—backed by expert guidance and on-ground support.

We give clear pricing. No hidden costs, no fake discounts, just honest rates you can trust.

98% of our clients succeed in FSSC 22000 certification audits as our proven process ensures reliable compliance.

Our experts offer complete FSSC 22000 consultancy, fix real factory gaps, and ensure confident, fast, audit-ready compliance.

FSSC 22000 certification shows that your facility complies with international food safety standards, reduces operational risks, and builds buyer confidence. At Legal4sure, our professionals work with your team to implement every requirement, making your organization completely prepared to be audited, and ready to expand in global markets.

In order to meet international standards and gain customer trust, FSSC 22000 ensures end-to-end food safety by providing strong hazard controls, hygiene procedures, traceability systems, and continuous improvement throughout the manufacturing process.

Risk-based HACCP systems help factories control food safety hazards early, ensuring consistent product safety and meeting global food safety requirements under the FSSC 22000 framework.

FSSC 22000 helps factories gain global market acceptance by meeting international food safety norms, building buyer trust, and unlocking access to exports, retailers, and high-value supply chains.

Legal4sure helped 1,500+ factories get FSSC 22000 certified with full support, fast compliance, and stress-free audit success.

98% success rate, because when we guide you, audits feel simple, not stressful.

We’ve worked with over 25 top certifiers, so no matter who audits you, we know what they’ll expect.

Our experts offer complete support to help you meet FSSC 22000 certification requirements with confidence. From documentation, GMP systems, and internal audits to audit readiness and CAPA, we manage every step with precision. With over 1500+ FSSC 22000 projects delivered, our structured approach ensures smooth, timely certification without last-minute surprises.

We address every step leading up to your FSSC 22000 audit, from document review to an on-site walk-through. Our terrific experts will fill in any critical gaps, align your business practices with the standard, and then train your team to achieve an audit-ready experience and success.

We perform a full review of all your documentation, cleaning logs, traceability records, SOPs, and HACCP plans. Our FSSC 22000 consultants will examine every detail to ensure your factory addresses all requirements before the inspection.

Our experts develop feasible corrective action plans to resolve FSSC 22000 non-conformities and ensure they do not happen again, along with ensuring that your factory operations align with food safety requirements and do this without hindering productivity and workflow.

We train your staff to implement FSSC 22000 requirements with confidence, and we will organize all key documentation, SOPs, and HACCP documents, so that your factory is ready for audit day.

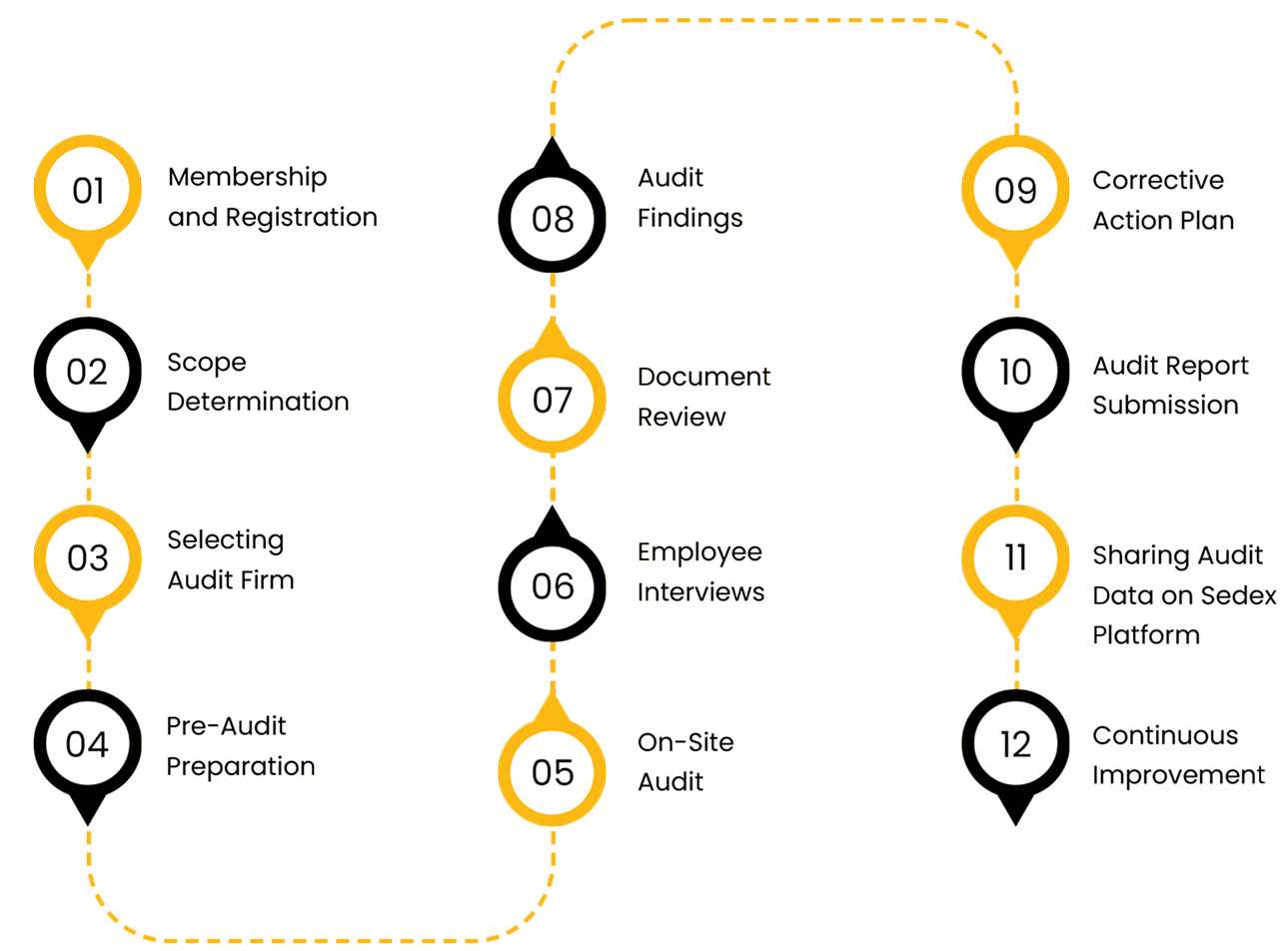

First, we verify that your factory meets the standards for the FSSC 22000 certification and assist you in understanding the requirements. We handle everything from FSMS creation, PRPs, HACCP, and internal audits to choosing a certification body. Our experts help you through Stage 1 and Stage 2 audits, take corrective measures, make sure you’re certified, and then carry out surveillance audits and ongoing improvement.

FSSC 22000 compliance covers food safety management, PRPs, HACCP, documentation, traceability, internal audits, and continual improvement. Legal4sure ensures full compliance by building your FSMS, reviewing critical records, aligning processes with ISO standards, and guiding you through audits. Trusted by global buyers, FSSC 22000 strengthens credibility and market access.

Here are Key tools: FSSC 22000 V6 documents and FSSC 22000 audit checklist.

Download the FSSC 22000 Version 6 Checklist to Prepare Your Factory for Audit.

Before working with us, most factories ask the same things. These FAQs cover what Legal4sure does and how we support you.

The worldwide food safety certification that buyers trust is FSSC 22000.It ensures that your facility complies with rigorous food safety and hygiene regulations if you export food or packaging.

If the paperwork, cleanliness, and procedures are in place, most factories may be certified in 30 to 60 days. This can be done more quickly and easily with professional assistance.

Risk management, food defense, validation, and improved documentation are the main topics of Version 6. Its goal is to make your systems better and satisfy contemporary consumer expectations.

FSSC 22000 is now anticipated by many foreign purchasers. Although it is not a legal requirement, failing to have it can reduce your likelihood of exporting, particularly to the Middle East and Europe.

ISO 22000 serves as the foundation for FSSC 22000, which includes additional safeguards for food safety. GFSI, which is favored by many purchasers, also acknowledges it. It’s a better and more well-liked iteration.

Costs depend on the size and readiness of the factory. For most Indian units, total costs range from ₹1.5 to ₹3.5 lakhs. This includes consultancy, training, and the certification audit.

You will need HACCP plans, SOPs, hygiene records, traceability files, cleaning logs, training records, and more. All documents should be organized and follow the latest Version 6 format.

Yes. We manage all aspects of your factory’s FSSC 22000 audit, including gap checks, paperwork, training, and mock audits. This way, you can pass without worry or last-minute stress.